Choosing the right garage floor coating is similar to laying a solid foundation for a house, and this process can be “daunting” due to a variety of options. This article provides a comprehensive guide to various coatings, delving into their pros, cons, costs, and maintenance requirements. Whether your priority is durability, aesthetics, or cost-effectiveness, this guide will equip you with the necessary insights to make an informed decision, ensuring your garage floor meets your specific needs and preferences.

Key Takeaways

- Epoxy coatings are favored for their durability, chemical resistance, and low maintenance.

- Polyaspartic and polyurea coatings have rapid curing times, excellent hot tire resistance, and provide a durable and glossy finish.

- Consider the cost of garage floor coatings and the return on investment in terms of extended floor life and reduced maintenance expenses.

- The choice between DIY and professional installation depends on individual circumstances and priorities, but professional installation provides expertise and a high-quality finish.

Types of Garage Floor Coatings

Choosing the appropriate garage floor coating depends on the user’s specific needs and preferences, considering key factors like durability, aesthetics, and maintenance.

Among the various floor coatings, epoxy coatings are often favored for their durability and chemical resistance. These coatings are also noted for their cost-effectiveness and the availability of DIY kits, making them a popular choice among homeowners. However, they may lack the hot tire resistance found in other options.

Polyaspartic and polyurea coatings, on the other hand, are known for their rapid curing times and excellent hot tire resistance. They offer high durability and chemical resistance, similar to epoxy coatings, but are usually more expensive and might require professional installation.

In essence, the choice between epoxy, polyaspartic, and polyurea coatings largely depends on your individual needs and budget. Prioritizing durability might lead you towards epoxy or polyaspartic coatings, while a preference for hot tire resistance and quick installation could make polyurea a more suitable choice. Regardless of the option chosen, it’s crucial to remember that proper maintenance will extend the lifespan of any floor coating.

Benefits of Epoxy Coatings

These coatings are known for their ability to withstand heavy traffic, impacts, and even chemical spills, making them an ideal solution for both residential and commercial garages. Epoxy coatings offer durability, cost-effectiveness, and chemical resistance.

The preparation of the garage floor prior to the application of epoxy coatings is critical for the success of adhesion testing. This usually involves cleaning, repairing any existing damage, and sometimes even grinding the surface for better adhesion. There are a variety of application tools available, from rollers and brushes to spray equipment, allowing for a smooth and even finish.

One of the main benefits of epoxy coatings is their low maintenance requirement. The finish coats are resistant to dust, dirt, and stains, making them easy to clean. Furthermore, they offer superior slip resistance, providing an extra layer of safety.

Lastly, despite the high-quality finish and durability, epoxy coatings are cost-effective. The initial investment can be quickly recovered through savings on maintenance costs and the extended lifespan of the garage floor. In conclusion, epoxy coatings provide a practical, durable, and aesthetically pleasing solution for garage floor coating.

Polyurea Garage Floor Coatings

Polyurea garage floor coatings are renowned for their rapid installation process. These coatings are compatible with concrete floors prevalent in most garages, offering a durable and glossy finish.

The application process involves three steps: priming, applying the base coat, and finally, the top coat. Primers ensure excellent adhesion to the concrete, while base coats serve as the main color layer. Top coats seal the surface, providing an improved gloss and added protection. During the base coat application, you can add colors, flakes, or traction additives to create a unique, visually appealing, and safe surface.

Here’s a comparison of two coating options:

| Epoxy | Polyurea | |

|---|---|---|

| Cure Time | Slow | Fast |

| Resistance | Moderate | High |

| Installation | Complicated | Simple |

| Appearance | Duller | Glossier |

| Durability | Lower | Higher |

Durability and Maintenance

Selecting the right garage floor coating product depends on its durability and maintenance requirements. A highly durable coating can withstand heavy traffic, resist chemical spills, and hide concrete defects such as cracks and spalling. This longevity reduces the frequency of maintenance tasks, making it a cost-effective solution in the long run.

Maintenance, on the other hand, involves the application of concrete sealers to protect the coating from moisture and stains. Depending on the severity of concrete defects, you may need to use repair products such as patch compounds, joint fillers, and crack fillers. These products not only restore the structural integrity of your garage floor but also prepare it for the application of the coating.

Cost Considerations

With regard to selecting a suitable garage floor coating, it’s essential to consider the cost implications, including upfront expenses and long-term maintenance costs. These costs vary depending on the garage type, whether it’s residential, commercial, or industrial.

Your budget will largely dictate the type of coating you can afford. Residential coatings are typically less expensive than commercial or industrial ones due to their lower durability requirements. Don’t forget to factor in the cost of renewal coatings, which are necessary to maintain the floor’s appearance and functionality over time.

Before making a decision, obtain multiple quotes from different suppliers. These quotes should provide detailed estimates that include the cost of materials, installation, and maintenance plans. Carefully comparing these quotes can help you identify the most cost-effective solution.

Consider the return on investment (ROI) as well. A higher upfront cost might be justified if the coating significantly extends the life of your garage floor or reduces maintenance expenses.

DIY Vs Professional Installation

After considering your budget and potential return on investment, you must also weigh the pros and cons of installing the garage floor coating yourself versus hiring a professional. In the debate of DIY vs professional installation, several factors come into play.

Doing it yourself may seem like a cost-effective option, but it requires a significant investment of time and energy. Reviews and buying guides can provide valuable insights, but there’s no substitute for professional expertise. Contractors have extensive knowledge and experience, allowing them to avoid common pitfalls and ensure a high-quality finish. They are also likely to offer a warranty, giving you added peace of mind.

However, not all contractors are created equal. Before making your decision, it’s important to conduct thorough comparisons and seek referrals. Check their certifications and look at case studies of their past work. A decision matrix can be a useful tool in this process, helping you to objectively evaluate your options.

Ultimately, the choice between DIY and professional installation depends on your specific circumstances and priorities. By doing your homework and considering all the relevant factors, you can make an informed decision that best suits your needs.

Coating Color and Texture Options

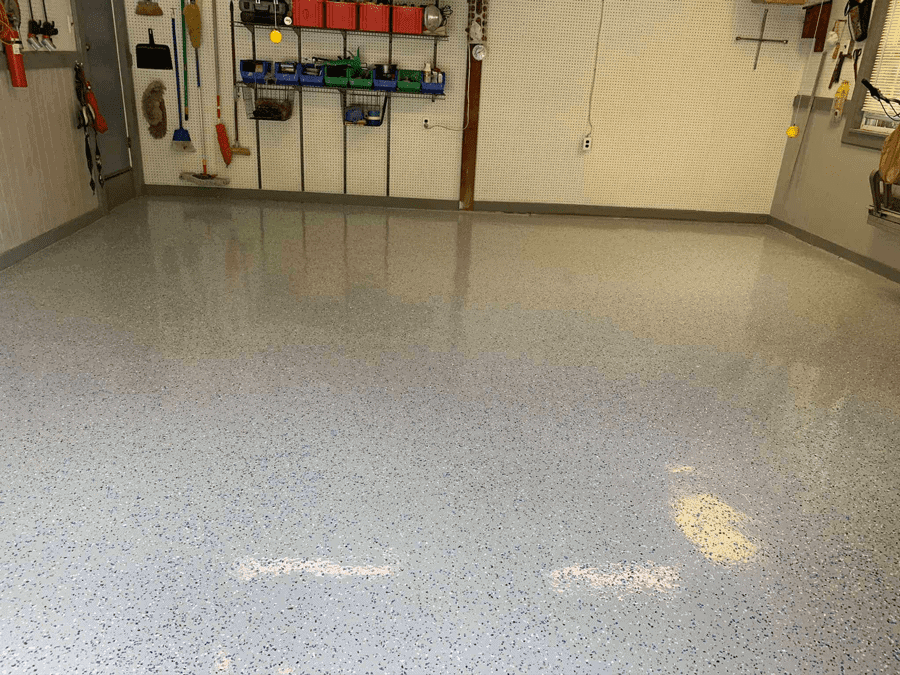

Continuing from the decision-making process of DIY versus professional installation, another significant consideration in selecting the right garage floor coating is the vast array of coating colors and texture options available in the market.

Coatings come in a plethora of colors, from traditional grays and blacks to metallic finishes, offering different gloss levels to suit individual aesthetic preferences. Cleaning and maintenance requirements can also vary depending on the color chosen. Darker shades can often help hide dirt and stains, making cleaning simpler.

Texture options are equally diverse, ranging from smooth, high-gloss finishes to more textured, non-slip options. Materials used can include quartz, terrazzo, and other aggregates, each providing a unique texture and aesthetic appeal.

Custom designs are another way to personalize your garage floor. You can opt for a simple, single color coating or intricate, multicolored designs, including the use of acid stains for a truly unique look.

Garage floor coatings can also come with sparkling finishes, giving your garage a luxurious look. However, these may require more diligent sealing to maintain their appearance.

Preparation for Coating Application

Before applying the chosen garage floor coating, it’s crucial to properly prepare the surface to ensure a successful and durable finish. This process involves a series of steps that require strategic execution and attention to detail.

- Surface Etching: Etching refers to the process of abrading the concrete to remove surface contaminants such as dust and oil and to open up the pores of the surface for better adhesion. This is a vital step and should be done using safety gear like respirators to protect against the dust generated.

- Moisture and Climate Control: It’s important to assess the moisture level of the concrete and ensure climate control. High moisture levels can prevent the coating from adhering correctly. Additionally, temperature and humidity need to be regulated, as they can influence drying times and the mixing ratios of the coating materials.

- Lighting and Ventilation: Proper lighting is crucial to ensure even application of the coating. Ventilation is also important to evacuate fumes and dust. If the garage lacks natural ventilation, consider using fans.

Application Process Explained

In this section, we will meticulously break down the steps involved in the application process of your chosen garage floor coating. The process commences with thorough inspections to assess the current condition and moisture levels of the floor, which aids in moisture mitigation planning.

Next, the use of densifiers is crucial in preparing the floor for the coating. Densifiers increase the surface density and strength of the floor, thus creating an optimal surface for the coating.

Now, let’s dig into the coating itself. You will need to choose between water-based and solvent-based coatings, each with its own advantages and considerations. Water-based coatings tend to have lower VOC levels and are easier to apply, while solvent-based coatings often offer superior chemical resistance and durability.

Understanding coverage rates is key in precise application. It refers to how much area a certain amount of coating can cover. This ties directly into cure times, the duration it takes for the coating to dry and harden.

Understanding recoat times is also important, especially if multiple layers are required. Lastly, floor markings are applied if needed. These steps, executed properly, will ensure a successful and durable garage floor coating.

Curing Time and Conditions

While selecting the right garage floor coating, understanding the curing time and conditions is crucial as they significantly influence the durability and performance of the applied coating. The curing process is dependent on several factors, including temperature, humidity, and air movement.

- Toxicity: A key consideration during the curing process is the toxicity of the coating. Ensure adequate ventilation to minimize exposure to harmful fumes.

- Thermal cycling and UV resistance: The coating should withstand temperature fluctuations and resist UV rays. This will ensure its longevity under different weather conditions.

- Building codes and fire safety: Be aware of local building codes regarding the use of coatings in garages. Some coatings may require fire-rated insulation, especially in residential buildings.

The final appearance and durability of your garage floor coating are also influenced by other factors. For instance, cabinets and vehicle lifts may impact the even distribution of the coating. Anti-fatigue mats can protect the coating from heavy equipment or vehicles, extending its lifespan.

Dealing With Coating Failures

One must be well-prepared to handle potential coating failures, which can significantly impact the appearance and durability of your garage floor. Coating failures can result from a variety of factors, including improper preparation, application errors, and adverse environmental conditions.

A widespread issue includes the development of odors and the release of volatile organic compounds (VOCs), which are potential health hazards. Calcium sulfonate and polyisocyanurate, for example, could emit VOCs during heating. Aliphatic isocyanates, while providing excellent tensile strength and impact resistance, can also produce strong odors if not properly handled.

Proper organization and understanding of these materials and their potential risks are crucial in avoiding coating failures. Here’s a table summarizing some common failure causes and solutions:

| Cause | Effect | Solution |

|---|---|---|

| Improper preparation | Poor adhesion | Thoroughly clean and dry the floor before applying coating. |

| Application errors | Uneven coating, blisters | Follow manufacturer’s instructions carefully. |

| High VOC materials | Odors, potential health risks | Use low-VOC materials where possible. |

| Inadequate tensile strength | Cracking, peeling | Choose coatings with high tensile strength. |

| Poor impact resistance | Chipping, wear | Opt for coatings with high impact resistance. |

Longevity of Different Coatings

Given that coating failures can significantly affect the lifespan of your garage floor, it’s imperative to understand the durability of various coating options. The longevity of your garage floor coating depends on several factors, including the type of coating used, the quality of application, and its resistance to vehicle fluids such as gasoline, oil, antifreeze, and brake fluid.

Here are three broad categories of garage floor coatings, each with its unique durability characteristics:

- Epoxy Coatings: These are highly resistant to most vehicle fluids and are suitable for heavy-duty environments like workshops and auto repairs. They can last up to 20 years with proper maintenance.

- Polyaspartic Coatings: These coatings cure faster than epoxy and resist UV damage. Their highly durable nature makes them ideal for ramps and areas exposed to sunlight. However, they may require more frequent touch-ups.

- Concrete Sealers: Sealers like zinc primers are less durable but provide a natural look. They can last around 5 years before needing a re-coat.

Environmental Impact of Coatings

In light of the durability considerations, it’s equally important to examine the environmental impact of different garage floor coatings. Coatings can contribute to the pitting of the concrete surface, intensifying the efflorescence process that can lead to drains becoming blocked.

Notably, specific coatings may result in increased insurance claims due to slip fall accidents, particularly if proper sanitation measures are not observed during application. Professional associations and product manufacturers bear responsibility for ensuring that the environmental impact of coatings is minimized. The use of low volatile organic compounds (VOC) coatings, for instance, can reduce harmful emissions.

However, a common issue associated with epoxy coatings, often used for garage floors, is amine blush. This reaction between the epoxy and moisture in the air can lead to a compromised seal, disrupting the longevity of the coating and leading to potential environmental issues.

Troubleshooting Common Issues

Several common issues can arise when applying a garage floor coating, necessitating effective troubleshooting strategies for optimal results. These problems can be related to stairs, doors, shelving, signage, logos, single car, multi-car, various vehicle types, photos, and the phenomenon known as amine creep.

Here are three common problems and solutions:

- Amine Creep: This occurs when the epoxy coating creeps or moves from the applied surface. To prevent this, ensure that the surface is clean, dry, and adequately prepared before application. Use a primer to enhance adhesion, especially for multi-car garages with heavy traffic.

- Signage and Logos: These are tricky as they need to remain visible despite the coating. Use a clear coat over the signage and logos to protect them, while maintaining their visibility.

- Coating Around Stairs and Doors: These can be challenging due to their angles and edges. Use a smaller brush for precision application around these areas. Also, consider using photos to document the process for future reference.

Troubleshooting common issues in garage floor coating ensures a durable and aesthetically pleasing result. Knowledge of these problems and their solutions will result in a professional finish, regardless of the size or type of garage.

Tips for Coating Maintenance

To ensure your garage floor coating stands up to the test of time, regular maintenance is critical. This is the case whether your garage houses sports cars, trucks, or motorcycles, or it serves as a space for hobbies, a gym, or even a man cave. The coating is not just a functional layer, but it can also be an aesthetic addition with stencils or racing stripes, adding to the appeal of your space.

A good maintenance routine starts with a comprehensive checklist. Regular sweeping and cleaning is a must to keep dust and debris from scratching the surface. For tougher stains, a mild detergent should suffice. It is essential to avoid harsh chemicals which can damage the coating. Spills should be cleaned up promptly to prevent staining.

If your garage is a high-traffic area, like a gym or boat garage, consider reapplying a top coat every few years to maintain the shine and protect against wear. And, remember, any significant cracks or chips may require professional attention. By following these tips, your garage floor coating will remain in top condition, ready to withstand whatever you throw at it.

Frequently Asked Questions

What Safety Measures Should I Follow When Applying Garage Floor Coatings?

When applying garage floor coatings, safety is paramount. Ensure proper ventilation, use protective clothing, gloves, and eyewear. Follow manufacturer’s instructions, handle materials responsibly, and dispose of waste correctly to minimize health and environmental risks.

Is It Possible to Mix Different Types of Coatings to Achieve a Specific Result?

Yes, it’s possible to mix different types of coatings to achieve specific results. However, this should be done carefully considering factors like compatibility, drying time, and desired finish to avoid undesired outcomes.

How Does the Climate or Weather Affect the Choice of Garage Floor Coating?

Climate greatly influences garage floor coating choice. Extreme temperatures can degrade certain coatings, while high humidity can affect curing times. Thus, understanding local weather patterns is crucial for selecting a durable, long-lasting coating.

Are There Any Health Risks Associated With the Long-Term Exposure to Certain Garage Floor Coatings?

Yes, certain garage floor coatings, particularly those containing volatile organic compounds (VOCs), may pose health risks. Long-term exposure can cause respiratory issues, eye irritation, and in severe cases, damage to the central nervous system.

Can Garage Floor Coatings Be Used on Other Surfaces Like Driveways or Patios?

Yes, garage floor coatings can be used on other surfaces like driveways or patios. However, their efficiency and longevity may vary due to differences in surface material and exposure to varying weather conditions.

Conclusion

In conclusion, selecting the right garage floor coating necessitates thorough understanding of the different options, their pros and cons, cost, durability, appearance, and maintenance requirements. The ideal coating should not only offer durability but also enhance aesthetic appeal. By considering these factors, individuals can make an informed decision, ensuring a garage floor coating that aligns with their specific needs, ultimately creating a functional, durable, and visually pleasing garage space.